In the hyper-competitive business arena, a finely tuned supply chain isn’t just a nice-to-have—it’s your lifeline. With shrinking margins and soaring customer expectations, your supply chain’s efficiency directly impacts your bottom line, customer loyalty, and resilience in the face of disruption.

Imagine slashing costs, boosting efficiency, and consistently exceeding customer expectations. That’s the power of an optimized supply chain, and industry giants like Microsoft and Meta have already harnessed this power with Algo, an AI-powered supply chain intelligence platform.

Microsoft: Optimized inventory allocation and streamlined forecasting for faster, data-driven decisions.

Meta: Integrated siloed data and optimized global inventory allocation, providing planners with actionable insights for growth.

Adopting a solution isn’t a one-size-fits-all solution. At Algo, we understand your supply chain is unique, and we’re here to tailor our technology and expertise to your specific needs. In this blog, we’ll dive deep into how our personalized approach can revolutionize your supply chain, from crafting a winning strategy to seamless implementation and continuous optimization. Get ready to discover how Algo can transform your supply chain from a cost center into a profit-driving powerhouse.

3 Common Reasons Clients Choose Algo

Does your supply chain struggle with fragmented data? Or perhaps you’re facing complex global inventory allocation challenges? You’re not alone.

These are common pain points for businesses of all sizes, and they can significantly impact your bottom line. Major brands like Microsoft, Meta, and Best Buy have faced similar challenges—and they’ve turned to Algo’s AI-powered platform for solutions. Here’s why:

To Eliminate Fragmented Data Silos

Meta struggled with fragmented data spread across multiple systems, hindering their ability to make informed decisions. Algo seamlessly integrates these disparate sources, providing a unified view of your supply chain. This holistic view empowers you with real-time insights, enabling you to identify bottlenecks, optimize inventory, and make data-driven decisions that drive growth.

To Optimize Inventory and Enhance Profitability

Excess inventory ties up valuable capital and incurs unnecessary holding costs, while stockouts lead to lost sales and dissatisfied customers. Algo’s AI-powered algorithms analyze historical data and demand patterns to accurately forecast future needs. This enables you to maintain optimal inventory levels, reducing costs and ensuring products are available when customers want them.

To Improve Forecasting Accuracy and Streamline Planning

Inaccurate forecasts can wreak havoc on your supply chain, leading to overproduction or missed sales opportunities. Algo’s machine learning models continuously learn and adapt, providing more precise demand forecasts. This empowers you to make informed production and planning decisions, ensuring your supply chain operates smoothly and efficiently.

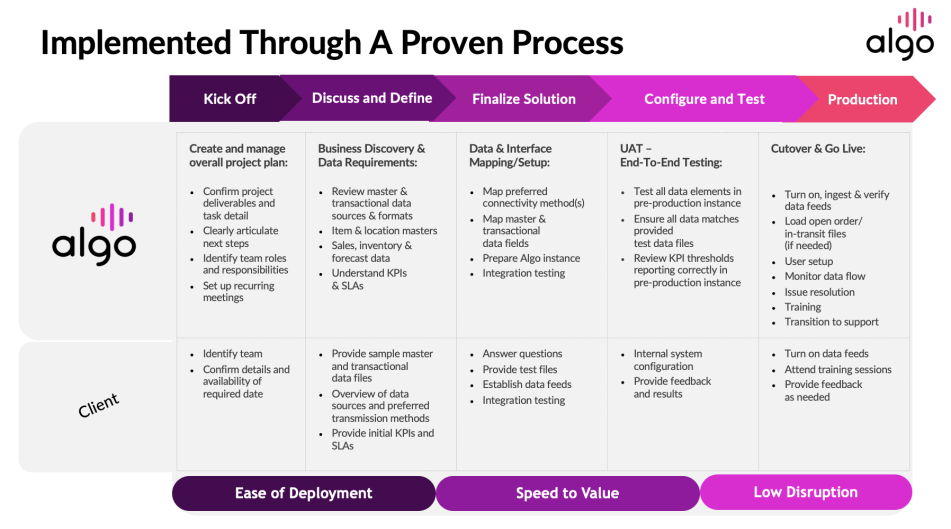

Adopting Algo: The Onboarding Process

At Algo, we understand that transitioning to a new supply chain platform can be complex. That’s why we’ve designed a comprehensive onboarding process that prioritizes collaboration, efficiency, and your success.

We sat down with Diane Sherwood, Algo’s Global Services SVP, to discuss the company’s unique approach to onboarding new clients. Here’s what she had to say:

“At Algo, we understand that transitioning to a new supply chain platform can be complex. That’s why we’ve designed a comprehensive onboarding process that prioritizes collaboration, efficiency, and your success. Our goal is to empower your team to harness the full potential of our AI-powered solutions as quickly and seamlessly as possible.”

But what does that look like in practice? Let’s break down the key steps of Algo’s onboarding journey, as explained by Diane:

Discovery and Assessment: Laying the Foundation for Success

We kick off our onboarding journey with a deep dive into your unique supply chain landscape. This isn’t just a surface-level overview – we’re talking about a comprehensive discovery and assessment process designed to uncover the hidden opportunities and challenges that lie beneath the surface.

Here’s how we approach it:

- In-Depth Discussions: We’ll sit down with your key stakeholders, from executives to frontline planners, to gain a holistic understanding of your business goals, strategic priorities, and pain points. We want to know what keeps you up at night and where you see the most potential for improvement.

- Data-Driven Analysis: Our team of data experts will meticulously analyze your historical data, identifying trends, patterns, and anomalies. This analysis helps us pinpoint areas of inefficiency, excess costs, and untapped potential within your supply chain.

- Infrastructure Assessment: We’ll assess your existing systems, processes, and technologies to understand how they’re currently supporting your supply chain. This allows us to identify gaps, redundancies, and opportunities for integration with Algo’s platform.

By the end of this phase, we’ll have a crystal-clear picture of your supply chain’s strengths, weaknesses, and areas where Algo can deliver the most significant impact. This deep understanding is the foundation upon which we’ll build a tailored solution that aligns perfectly with your unique needs and goals.

Collaborative Planning: Crafting Your Roadmap to Supply Chain Success

Once we’ve gained a deep understanding of your unique challenges and opportunities, we shift gears into collaborative planning mode. This is where we roll up our sleeves and work hand-in-hand with your team to design a detailed implementation roadmap that’s perfectly aligned with your specific goals, priorities, and timeline.

Here’s a glimpse into our collaborative planning process:

- Goal Alignment: We’ll revisit your business objectives and translate them into actionable supply chain targets. This ensures that every step of our implementation plan is focused on driving tangible results that matter to your bottom line.

- Prioritization: We understand that not all initiatives are created equal. Together, we’ll prioritize the areas where Algo can deliver the most immediate and impactful improvements, whether it’s reducing excess inventory, improving forecast accuracy, or streamlining replenishment processes.

- Timeline Development: We’ll create a realistic timeline that outlines key milestones, deliverables, and dependencies. This provides transparency and ensures that everyone is on the same page regarding expectations and deadlines.

- Resource Allocation: We’ll work with you to determine the resources needed for a successful implementation, both from your team and from Algo. This includes identifying key stakeholders, assigning roles and responsibilities, and establishing clear communication channels.

- Continuous Feedback Loop: Throughout the planning process, we’ll maintain an open feedback loop with your team. We encourage questions, suggestions, and course corrections as needed to ensure the plan remains dynamic and responsive to your evolving needs.

By the end of this phase, you’ll have a clear, actionable plan that outlines the steps we’ll take together to transform your supply chain. This plan will serve as our roadmap to success, guiding us through the implementation process and beyond.

Seamless Implementation: Your Supply Chain Transformation, Simplified

With a clear roadmap in hand, we move into the implementation phase, where your vision for a transformed supply chain begins to take shape. But rest assured, this isn’t a DIY project – our experienced team of supply chain and technology experts takes full ownership, guiding you through every step of the journey.

Here’s how we ensure a seamless transition:

- Dedicated Project Management: We assign a dedicated project manager to oversee your implementation, ensuring clear communication, coordination, and adherence to the agreed-upon timeline.

- Technical Expertise: Our seasoned engineers and data scientists handle the technical heavy lifting, configuring Algo’s platform to align perfectly with your unique requirements and integrating it with your existing systems.

- Data Migration and Validation: We meticulously migrate your data, ensuring accuracy and integrity throughout the process. We then validate the data within Algo’s platform to guarantee its reliability for analysis and decision-making.

- User Training and Enablement: We equip your team with the knowledge and skills needed to effectively use Algo’s tools and features. We provide comprehensive training sessions, documentation, and ongoing support to ensure your team is confident and proficient.

- Minimized Disruption: We understand that your business can’t afford downtime. That’s why we work closely with your team to minimize any disruption to your daily operations during the implementation process.

As Diane emphasizes, “Algo’s onboarding isn’t just about implementing software – it’s about building a lasting partnership. We’re dedicated to empowering your team with the tools and knowledge they need to achieve lasting supply chain transformation.”

Your Continuous Journey to Excellence: Ongoing Support and Optimization

At Algo, we believe that true partnership goes beyond implementation. That’s why our commitment to your success extends long after the initial rollout. We provide comprehensive support and optimization services to ensure you continue to extract maximum value from our platform.

Here’s how we support your ongoing success:

- Proactive Monitoring: We actively monitor your system’s performance, identifying potential issues before they impact your operations. This proactive approach ensures that your supply chain runs smoothly and efficiently.

- Data-Driven Insights: We regularly analyze your supply chain data to uncover new opportunities for optimization. We share these insights with you, along with actionable recommendations to help you continuously improve your performance.

- Ongoing Training and Education: We offer ongoing training and educational resources to keep your team up-to-date on the latest features, best practices, and industry trends. This ensures that you’re always leveraging the full power of Algo’s platform.

- Continuous Improvement: We believe in a culture of continuous improvement. We regularly gather feedback from your team, incorporate your suggestions, and refine our platform to meet your evolving needs.

As Diane emphasizes, “Algo’s onboarding isn’t just about implementing software – it’s about building a lasting partnership. We’re dedicated to empowering your team with the tools and knowledge they need to achieve lasting supply chain transformation.”

Algo Implementation: The Time to Full Implementation

While Algo is committed to rapid time-to-value, the exact timeframe for implementation varies depending on several factors. Our typical pilot implementation ranges from 1 to 12 weeks, but the overall duration can be influenced by:

- Complexity of Your Supply Chain: Larger, more complex supply chains with diverse product lines, multiple locations, and intricate processes naturally require more time to implement than smaller, simpler ones.

- Data Integration Requirements: If you have numerous data sources or legacy systems that need to be integrated with Algo’s platform, it can extend the implementation timeline. However, our team of experts is adept at handling even the most complex data integration scenarios.

- Customization Needs: While Algo’s solutions are designed to be flexible and adaptable, some businesses may require specific customizations to meet their unique requirements. This can add time to the implementation process but ensures that the solution perfectly fits your needs.

- Internal Resource Availability: The availability of your team members to participate in the implementation process can also impact the timeline. We’ll work with you to establish a realistic schedule that aligns with your team’s capacity.

Is Algo Right for Your Business?

By now, you’ve seen how Algo has revolutionized the supply chains of industry giants and addressed common challenges faced by businesses of all sizes. But is Algo the right fit for your specific needs?

If you’re grappling with any of the following, Algo could be the game-changer your supply chain needs:

-

- Data Silos: Are you struggling to get a clear picture of your supply chain because your data is scattered across different systems?

- Inventory Challenges: Do you find yourself constantly battling stockouts, overstock, or inefficient inventory allocation?

- Inaccurate Forecasting: Are you relying on outdated forecasting methods that lead to missed opportunities or excess inventory?

- Manual Processes: Are manual tasks bogging down your team and hindering efficiency?

- Lack of Visibility: Do you feel like you’re flying blind when it comes to your supply chain’s performance and potential risks?

If you answered “yes” to any of these questions, Algo can help. Our AI-powered platform, tailored implementation process, and commitment to your success have proven to deliver results time and again. We’ll work closely with you to understand your unique challenges and goals, then customize a solution that drives measurable improvements in your supply chain performance.

Don’t let supply chain complexities hold your business back. Take the next step and explore how Algo can empower your organization to achieve its full potential.

About the author

Karen McNaughton

Karen is the Vice President of Global Marketing at Algo, where she leads strategies to enhance brand awareness and demand generation for the company’s supply chain intelligence platform. With over twenty years of experience in senior marketing roles at various SaaS technology organizations, Karen brings extensive expertise in leading global marketing teams and executing go-to-market strategies.