Supply chain challenges

The consumer electronics client faced several critical challenges that hindered their supply chain efficiency and limited their ability to respond to market demands effectively.

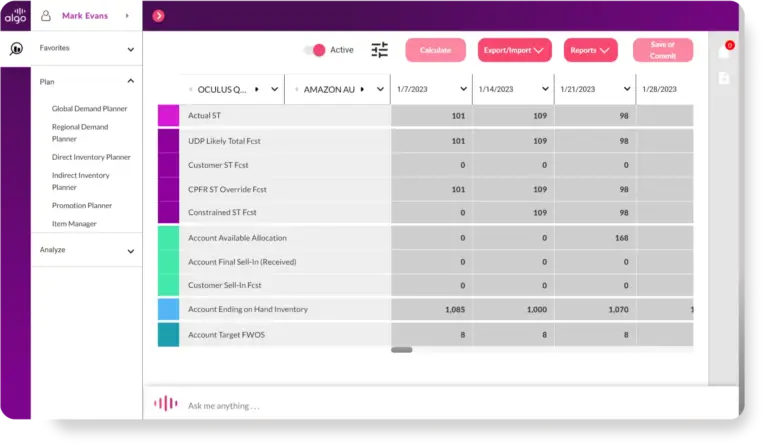

Algo’s solution

To address their challenges, Algo implemented a suite of advanced solutions that transformed the client’s supply chain operations and enhanced their overall efficiency.

The results

The client experienced significant improvements in revenue, inventory management, and decision-making capabilities.

They identified over $500k in sales opportunities in a single week by optimizing inventory allocation, reduced out-of-stock situations, and minimized excess inventory. The integration of advanced analytics and real-time data enabled faster, more accurate decisions, positioning the client for sustained growth and greater operational efficiency.