Supply chain challenges

The Australian tech and home appliances brand struggled with accurately estimating lost sales due to stockouts, which resulted in suboptimal inventory decisions and customer dissatisfaction.

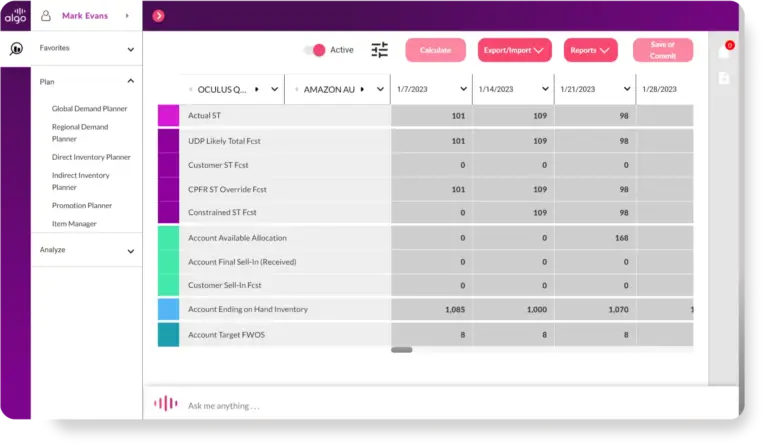

Algo’s solution

The brand used Algo’s Intelligent Inventory Optimizer to improve lost sales estimates, optimize substitutions, and enhance inventory decisions, leading to reduced stockouts and operational costs.

The results

By implementing Algo’s Intelligent Inventory Optimizer, the brand achieved significant improvements across key areas of their supply chain, leading to notable reductions in lost sales, enhanced forecasting, and overall operational efficiency.

- 30% Reduction in Lost Sales: The implementation of Algo’s IIO led to a significant 30% decrease in lost sales within the first six months, improving the company’s overall revenue and profitability.

- Enhanced Forecasting Accuracy: By considering distribution center stock levels and real-time data, the brand improved the accuracy of its sales forecasts, allowing for better inventory management and planning.

- Increased Customer Satisfaction: The ability to offer substitute products and reduce stockouts resulted in higher customer satisfaction and strengthened loyalty to the brand.

- Cost Savings on Replenishments: Accurate demand forecasting and inventory optimization reduced the need for costly emergency stock replenishments, resulting in substantial cost savings and improved operational efficiency.