Supply chain challenges

The company needed to replace inefficient, siloed spreadsheet-based planning systems with a more integrated approach that consolidated data and enhanced cross-functional collaboration.

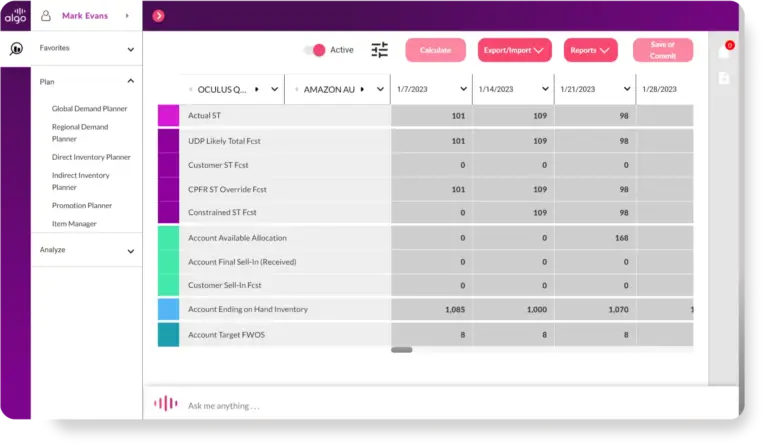

Algo’s solution

Algo helped the company overcome its supply chain challenges and achieve significant improvements in forecast accuracy, inventory management, cross-functional collaboration, and overall visibility.

The results

The implementation of Algo’s solutions led to several significant results for the company:

- Increased Forecast Accuracy: The company achieved a 20% improvement in forecast accuracy, allowing for more precise demand and inventory planning.

- Improved Cross-Functional Collaboration: The new system facilitated better collaboration between different teams by providing a unified view of data, helping to break down silos and ensure that everyone was working with the same information.

- Enhanced Visibility Across Teams and Leadership: The company gained greater visibility into key supply chain metrics, both at the team level and for leadership, leading to more informed and effective decision-making.

- Accelerated Adoption of Advanced Planning Tools: The user-friendly features and robust reporting capabilities of Algo’s solutions led to higher and increasing adoption rates across the company, ensuring that the new tools were effectively utilized.

- Better Understanding of Inventory Positions: The real-time inventory planning tools provided a clearer view of inventory positions, enabling more accurate and timely adjustments to meet customer demand.

These results collectively helped the company to modernize its supply chain operations, leading to more efficient processes and improved overall business performance.